As the manufacturing segment gears up for the next phase of growth wherein connected devices powered by IoT, AI, machine learning will amplify the productivity with minimal human intervention, identification and implementation of right technology solutions are going to be extremely critical for the industries globally.

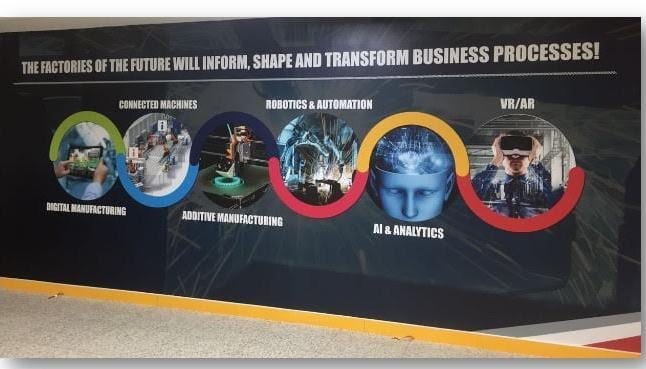

Tech Mahindra has set up a state-of-the-art lab which works on technologies that are expected to power the future factory floors. Known as the “Factory of the Future” lab, the new centre showcases assets and solutions in the areas of Digital Manufacturing, Connected Machines, Addictive Manufacturing, Robotics & Automation, Artificial Intelligence & Analytics, and Augmented Reality & Virtual Reality.

The lab will demonstrate solutions and products built in association with many leading software and hardware vendors. It is built in modular form to showcase Industry 4.0 concepts that are central to be able to help building the Digital backbone of client organizations.

“Industries world-over are going through a massive transformation, a transformation that is driven by the advances in newer technologies, especially things like IoT and Robotics. As a trusted Digital Transformation partner for client organizations, we have taken lead in these areas and have invested in building capabilities to harness the opportunities,” said L Ravichandran, President and Chief Operating Officer at Tech Mahindra.

“We believe that we have the unique skills and technology depth to help our clients to be ready for Industry 4.0 with minimal disruption,” said Aloke Palsikar, Senior VP and Global Head of Manufacturing at Tech Mahindra. “The infrastructure and the assets in the lab are already being monetized to create customer-centric solutions and we already have some references while some of the customer use cases are being tested.”

Manufacturing or industrial segment is the one where the impact of technology is much more visible that others. From being a mostly people or labour-intensive model in the late 80`s, to adopting to the automation tools, software and platforms, manufacturing at presently is a greatly transformed segment. The industry is now at a cusp of embracing the next generation of automation wherein robots will work alongside humans in a connected factory floor that is powered by technologies such as AI, Robotic & Automation, Machine Learning amplified by increasing use of Big Data and Analytics in decision-making.

In the newer phase, technology will be the main backbone of the manufacturing industry which is expected to shed around 50 million jobs globally while at the same time improving the efficiency and productivity significantly, because of the investment in new automation capabilities.

“Advances in robotics are more than just capabilities and cost,” according to research and advisory firm IDC. “They are becoming more collaborative with an ability to be programmed on the fly and work with humans rather than sitting behind a fence doing a single task programmed for it,” IDC said in a report on Industry 4.0 commissioned by Tech Mahindra. The research firm estimates that by 2020, nearly two-thirds of all work in factories will be completed by one of these “cobots” or collaborative robots while robotics will have five times the capability at one-fifth the cost of what was available in 2015.